Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-10-24 Origin: Site

Choosing the wrong CNC Polishing Machines wastes time and money. The right machine improves workflow, surface finish, and long-term productivity. In this article, you will learn how to select wisely by evaluating materials, machine types, and cost factors.

Different materials require different polishing approaches. Metals such as aluminum, stainless steel, and titanium respond differently to polishing pads and spindle speeds compared to plastics or composites. It is essential to match the CNC Polishing Machines spindle power to material hardness. Equally important is choosing compatible polishing media to avoid scratches or uneven finishes. By understanding material properties, you ensure consistent quality across parts and reduce tool wear.

Your surface finish requirements influence machine selection directly. Whether you need rough, satin, glossy, or mirror finishes, the machine’s capabilities must align with these targets. Specifications such as roughness average (Ra) and gloss level determine the polishing technique and cycle time. Integrating these factors into your factors to consider when choosing CNC polishers ensures that the final product meets both aesthetic and functional standards.

Production requirements vary widely. Small-batch workshops may prioritize flexibility, while high-volume production demands efficiency and speed. The throughput of CNC Polishing Machines must match workflow demands, avoiding bottlenecks or overinvestment. It is important to assess both cycle time and setup duration to optimize your operations. Flexible machines that can handle both low- and high-volume tasks often offer the best return on investment.

Industries like aerospace, medical, and electronics require high-precision polishing. Tight tolerances impact spindle selection, tooling, and polishing techniques. Machines capable of maintaining micron-level accuracy are essential to avoid costly rework. Considering key considerations in CNC polishing machine purchase, prioritize machines with robust frames, vibration damping, and precise CNC control systems. Precision should never be compromised, even for higher speed or cost savings.

Vertical machines offer easy access for taller parts, while horizontal machines handle heavier loads efficiently. Part geometry often dictates the orientation to ensure optimal polishing angles. Vertical polishers are suitable for lightweight or delicate components, whereas horizontal systems excel at bulk production. By evaluating your workflow, you can choose the orientation that balances efficiency and quality.

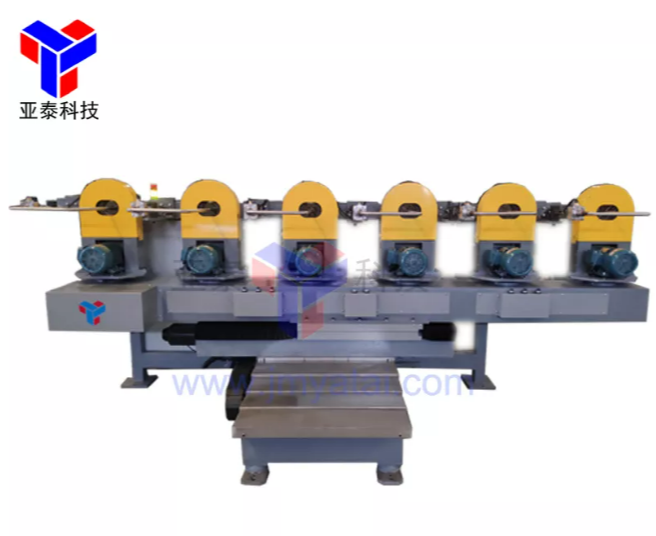

Multi-axis systems, including 3-axis, 4-axis, and 5-axis machines, provide superior control over complex surfaces. They are ideal for parts with intricate curves, contours, or deep recesses. By employing CNC polishing machine application scenarios, these machines allow precise movement and consistent finishing across all surfaces. Investing in multi-axis systems can significantly reduce manual labor while improving uniformity.

Fully automated systems minimize operator intervention, increasing throughput for repetitive tasks. Semi-automated systems combine human judgment with machine precision, ideal for complex or custom parts. Automation reduces labor costs and maintains consistency in high-volume environments. Deciding between automated and semi-automated systems depends on your production scale, budget, and quality expectations.

Hybrid machines combine CNC automation with manual finishing capabilities. They allow flexibility for delicate or irregular parts while maintaining overall efficiency. Hybrid setups can optimize cost-performance ratios, especially in workshops handling both standard and custom orders. Evaluating these systems within the key considerations in CNC polishing machine purchase helps balance flexibility, cost, and quality.

Spindle specifications are fundamental to achieving efficient polishing results. Machines with higher spindle power can remove material faster but may produce excess heat if not matched to the material’s hardness. Variable RPM settings allow one machine to handle metals, plastics, and composites efficiently, providing versatility across different projects. Aligning spindle power and speed with material properties ensures consistent surface quality, extends tool life, and prevents premature wear on both tooling and machine components. Proper spindle selection also influences overall throughput, particularly in high-volume production scenarios.

The choice of polishing pads, brushes, and compounds directly impacts finish quality and operational efficiency. Quick-change tooling significantly reduces downtime, supporting continuous workflow in busy workshops, while fixed tooling offers stability for tasks requiring ultra-precise tolerances. Selecting consumables based on material type and desired surface finish prevents defects such as scratches, uneven gloss, or color inconsistencies. Regular inspection and replacement of worn pads or brushes maintain consistent results. Understanding how each consumable interacts with your workpiece allows operators to optimize polishing cycles and reduce material waste, improving overall process economics.

Factor | Recommendation | Notes |

Part Size | Ensure machine handles largest part | Leave clearance for fixtures and jigs |

Work Envelope | Select for current and future needs | Future-proofing prevents costly upgrades |

Floor Space | Match footprint to workshop layout | Consider operator movement and material flow |

The machine’s work envelope must accommodate both current and anticipated production needs. Choosing a larger envelope ensures that oversized or future components can be polished without replacing the machine. Adequate planning also improves operator safety, workflow efficiency, and material handling logistics. Considering part fixtures, jigs, and loading/unloading processes during selection prevents production bottlenecks and maximizes the machine’s operational lifespan.

Control systems define how effectively a CNC polisher can operate. User-friendly interfaces reduce training time and minimize operational errors, while robust software ensures repeatability and consistent surface quality. Integration with CAD/CAM software improves workflow efficiency and enables precise program execution. When selecting a system, consider your team’s experience to ensure compatibility with existing processes. Advanced features such as multi-axis programming, customizable sequences, and error monitoring enhance productivity, particularly in complex polishing applications or high-mix production environments. Prioritizing intuitive and reliable controls mitigates human error and boosts overall output.

Routine maintenance is crucial to preserve both precision and machine lifespan. Tasks such as lubrication, alignment verification, and inspection of mechanical and electronic components prevent premature wear. Scheduling maintenance systematically reduces unexpected downtime and maintains consistent surface finish quality across production batches. Keeping detailed maintenance logs allows early identification of emerging issues, enabling proactive corrections before they disrupt workflow. Consistent upkeep also supports warranty compliance and enhances resale value, ensuring the CNC polishing machine remains a long-term asset for your workshop.

Understanding common CNC polishing machine issues—like spindle vibration, inconsistent feed, or tool wear—empowers operators to respond quickly and minimize production losses. Structured troubleshooting protocols and access to service manuals allow rapid diagnosis, while having trained technicians on-site ensures that repairs are handled efficiently. Prompt intervention reduces the risk of extended downtime and prevents secondary damage to machine components. Investing in thorough documentation, spare parts inventory, and operator training enhances overall reliability and preserves the machine’s performance in both short-term and long-term operations.

A machine’s structural integrity is vital for precision and longevity. High-quality frame materials, rigidity, and vibration damping directly affect surface finish and tolerance adherence. Machines with superior construction resist deformation under heavy loads, maintaining accuracy even during continuous operation. Evaluating build quality during the purchase stage prevents future repair costs and ensures that machines can withstand demanding industrial environments. Attention to structural design, joint stability, and material resilience contributes to consistent performance, particularly when polishing complex geometries or high-hardness materials.

Balancing upfront cost against long-term ROI is essential when acquiring CNC polishing machines. Entry-level systems are suitable for small-scale workshops, mid-range models support growing operations, and high-end machines cater to precision-intensive industries. Evaluating factors to consider when choosing CNC polishers—including material compatibility, automation requirements, and production volume—ensures that investment aligns with operational objectives. Proper financial planning allows businesses to avoid overspending on unnecessary features while securing machines capable of meeting current and future demands efficiently.

Electricity, tooling, consumables, and maintenance contribute to the total cost of ownership. Assessing these expenses upfront enables accurate budgeting and cost optimization strategies. Energy-efficient machines reduce ongoing operating expenses without sacrificing performance, while careful selection of consumables minimizes waste and extends tool life. Monitoring operational costs over time helps managers identify efficiency improvements, such as adjusting polishing parameters, optimizing tool usage, or implementing predictive maintenance schedules.

New CNC polishers provide warranty coverage, modern technology, and predictable performance, albeit at higher costs. Used machines reduce capital expenditure but require thorough inspection for wear, spindle hours, and remaining lifespan. Evaluating the condition, service history, and compatibility with existing workflows ensures reliability and prevents hidden costs. For businesses aiming to maximize ROI, a carefully chosen used machine can offer significant savings without compromising quality or productivity, provided that maintenance and potential upgrades are considered.

Leasing CNC polishing machines preserves working capital and allows access to modern equipment without a large upfront investment. Financing spreads the purchase cost, making high-end machines attainable for growing workshops. Comparing leasing and financing options against anticipated productivity gains helps businesses select the most advantageous financial arrangement. Flexible acquisition strategies enable workshops to scale operations quickly, integrate automation features, and maintain equipment at peak performance without straining budgets.

Machine placement directly influences productivity, safety, and workflow efficiency. Ensuring adequate clearance for operators, material handling equipment, and maintenance activities reduces bottlenecks. Strategically positioning machines along logical process flows minimizes operator movement and material handling time. Incorporating ergonomic considerations and safety pathways ensures compliance with workplace regulations and improves operator satisfaction, directly contributing to higher output quality.

Planning for additional machines, larger parts, or increased production volume prevents future operational disruptions. Selecting scalable or modular CNC polishing systems allows workshops to expand without costly infrastructure changes. Future-ready layouts account for space requirements, power supply, and workflow flexibility, enabling businesses to respond efficiently to evolving production demands or market growth.

Adequate ventilation, dust collection, and noise control are essential for operator safety and regulatory compliance. Controlling environmental factors reduces health risks, improves working conditions, and ensures consistent product quality. Effective dust and fume management also extends machine life by preventing abrasive particle buildup and corrosion, preserving both accuracy and reliability.

Integrating CNC polishing machines with conveyors, robotic loaders, or CAD/CAM systems enhances operational efficiency and reduces human error. Automated workflows accelerate production, particularly for high-volume or precision applications. Machines capable of seamless integration into interconnected production lines streamline operations, reduce manual intervention, and maximize return on investment. Automation also facilitates consistent surface finishes, repeatable processes, and improved overall throughput.

Selecting suppliers with proven reliability, spare parts availability, and responsive service is critical for maintaining continuous operations. Dependable technical support ensures rapid resolution of issues and minimizes production interruptions. Partnering with reputable suppliers also provides access to updates, training, and resources that enhance machine utilization and lifespan, directly supporting long-term operational efficiency.

Comprehensive warranty coverage protects critical components and ensures that major repairs are addressed promptly. Preventative maintenance programs offered by suppliers extend machine life and reduce unexpected costs. Evaluating warranty terms and after-sales support during key considerations in CNC polishing machine purchase enables businesses to safeguard investments and secure long-term operational stability.

Proper training ensures operators utilize CNC polishing machines safely and efficiently. Access to detailed manuals, online tutorials, and in-person workshops accelerates learning curves, reduces errors, and improves productivity. Training programs also empower operators to maintain machines properly, troubleshoot minor issues, and adapt to new processes, ensuring consistent quality and optimal machine utilization.

Consulting existing users provides valuable insights into machine performance, reliability, and supplier support quality. Benchmarking against industry standards validates claims and highlights practical advantages or limitations of specific CNC polishing machines. Gathering feedback from multiple sources aids informed decision-making, reduces purchasing risks, and strengthens confidence in supplier selection.

Choosing the right CNC Polishing Machines boosts efficiency and product quality. Evaluate materials, machine types, production needs, and costs carefully. Yatai Polishing Machine Co., Ltd. offers reliable machines with advanced features that enhance precision and workflow. Their CNC polishers deliver consistent finishes while supporting long-term productivity, making them a valuable investment for any workshop.

A: CNC Polishing Machines are designed to achieve precise and consistent surface finishes on metals, plastics, and composites. Using a CNC polishing machine selection guide helps match machines to specific material types and polishing requirements.

A: Consider production volume, desired surface finish, material type, and precision needs. Factors to consider when choosing CNC polishers ensure optimal efficiency, reduced downtime, and consistent results.

A: Machines include vertical, horizontal, multi-axis, automated, semi-automated, and hybrid systems. Evaluating CNC polishing machine application scenarios helps select the type that fits your workflow best.

A: Spindle power determines material removal rates and surface quality. Key considerations in CNC polishing machine purchase recommend matching spindle specifications to material hardness to avoid damage or inefficiency.

A: Regular maintenance, including lubrication and tool inspection, is essential but manageable. Using a CNC polishing machine selection guide can minimize downtime and reduce long-term operating costs.

A: New machines offer the latest technology and warranties, while used machines save upfront costs. Factors to consider when choosing CNC polishers help weigh long-term reliability against initial investment.

A: Consider factory layout, future expansion, and automation options. Reviewing CNC polishing machine application scenarios ensures smooth workflow integration and improved production efficiency.

A: They deliver consistent finishes, reduce labor, and improve precision. Key considerations in CNC polishing machine purchase emphasize efficiency, accuracy, and ROI for high-volume or precision tasks.

A: Address spindle vibration, inconsistent feed, or tool wear promptly. Using a CNC polishing machine selection guide helps anticipate issues and maintain reliable, high-quality production.