Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-16 Origin: Site

Do you know the difference between buffing and polishing? Many people use these terms interchangeably, but they’re far from the same.

In this article, we’ll explore the key differences between buffing and polishing. You’ll learn when and why each technique is used and how to achieve the best results with both methods.

Buffing is a surface finishing process that involves using a rotating wheel or pad in combination with an abrasive compound to smooth or shine a surface. This technique is primarily used to remove imperfections such as scratches, swirl marks, oxidation, and other surface flaws from a variety of materials, including metal, plastic, wood, and car paint. Buffing is a more aggressive technique than polishing, as it not only removes imperfections but also helps to level uneven surfaces, making them smoother.

Buffing is commonly applied in automotive detailing, where it is used to restore the shine of car paint by eliminating surface defects and oxidation. In furniture restoration, buffing can rejuvenate the finish of wooden pieces, removing minor scratches and scuffs that accumulate over time. Similarly, buffing is used on metals like aluminum, copper, and brass to prepare them for further treatments, such as polishing or coating. The process usually requires the use of different types of buffing wheels and compounds based on the material and desired finish. For example, coarser compounds are used in the initial stages to remove deep imperfections, while finer compounds are used for the finishing stage to smooth the surface and enhance its appearance.

Polishing, by contrast, focuses on achieving a high-gloss, mirror-like finish. This technique uses finer abrasives compared to buffing, making it a more refined process aimed at enhancing the shine and smoothness of an already relatively smooth surface. Polishing is typically used on surfaces like metal, stone, wood, and even plastic to bring out a reflective, glossy look.

The primary purpose of polishing is not to remove significant material but to refine the surface to a flawless shine. While buffing is often used to remove surface imperfections, polishing smooths out any remaining small scratches and adds the finishing touch to the surface. Polishing compounds, such as white or blue rouge, are designed to be less abrasive, ensuring the preservation of the material’s integrity while enhancing its visual appeal. This makes polishing ideal for applications where aesthetics and a glossy finish are the key goals, such as in jewelry making, marble or stone countertops, and high-end furniture finishing.

While buffing and polishing are often used interchangeably, they are distinct techniques with different purposes, processes, materials, and results. Understanding these differences is crucial for selecting the right approach based on the surface you’re working on and the finish you want to achieve. Let’s dive deeper into the key differences between buffing and polishing.

The primary purpose of buffing is to remove visible imperfections such as scratches, swirl marks, oxidation, and other surface flaws. Buffing is ideal for smoothing rough surfaces, bringing them to a relatively even texture. It is typically used when a material has visible imperfections or has been exposed to wear and tear, such as in automotive detailing or furniture restoration. Buffing prepares the surface for further treatment, such as applying a coat of paint, a protective finish, or polishing.

Buffing is often the first step when preparing surfaces that need restoration or a smooth base. It’s especially effective at dealing with materials that have a more noticeable texture or imperfections. When used properly, buffing restores the surface’s integrity, ensuring that subsequent processes can be applied effectively.

On the other hand, polishing is focused on refining the surface and enhancing its shine to create a high-gloss, mirror-like finish. Polishing is generally done after buffing and is used to smooth out remaining imperfections that are too fine for buffing compounds to address. The goal is to improve the surface’s aesthetic appeal and create a reflective, glossy finish.

Polishing is typically used on surfaces that are already smooth but need extra shine or refinement. It’s most often used as a final step in surface finishing, especially when the goal is to highlight the material's natural sheen or achieve a glossy appearance, such as in jewelry making or fine furniture finishing.

Buffing generally follows a two-step process to achieve a smooth surface:

1. Cut Buffing: In the first step, buffing uses coarser compounds to remove deeper imperfections such as heavy scratches, oxidation, and rough patches. These compounds are more abrasive and help to level out the surface, smoothing out the material's texture.

2. Color Buffing: Once the initial imperfections have been removed, color buffing is done using finer compounds. This step refines the surface, ensuring that it becomes smoother and ready for the finishing process. The aim here is to bring out the best possible sheen without overworking the surface.

While the buffing process can be intensive and aggressive, it is essential to apply the right amount of pressure and use the appropriate compound for each stage to avoid damaging the surface.

Polishing, in contrast, is typically a single-stage process. It uses finer abrasives that are much less aggressive than the compounds used for buffing. The abrasive particles in polishing compounds are designed to smooth out minor scratches and imperfections while enhancing the surface’s gloss. Polishing compounds can be applied by hand or with a machine, and they often leave a mirror-like finish on the surface.

Unlike buffing, polishing does not remove substantial material but focuses on refining the surface’s shine, making it ideal for enhancing materials that have already been buffed or otherwise pre-treated.

Buffing typically involves coarser compounds designed to remove visible imperfections from a surface. Some common materials used in buffing include:

● Black Emery: Often used for cut buffing, this compound is highly abrasive and effective at removing heavy scratches and surface imperfections.

● Brown Tripoli: A versatile compound that works well for both cut buffing and color buffing, helping to smooth rough surfaces and remove deeper flaws.

● Green Rouge: A finer abrasive, used in the later stages of buffing to bring out a moderate shine.

● White Rouge: Used in the final stages of buffing, white rouge produces a smooth, shiny surface without over-polishing.

The choice of buffing compound depends on the type of material and the depth of imperfections that need to be addressed. The more aggressive compounds are used for deep scratches, while finer compounds are used for finishing.

Polishing uses finer abrasives designed to smooth out minor imperfections and enhance the surface’s gloss. Some common materials used for polishing include:

● White Rouge: A fine abrasive used for polishing metals, particularly stainless steel, and achieving a reflective finish.

● Blue Rouge: This compound is often used for polishing plastics and softer metals, offering a smooth, high-gloss finish without damaging the material.

● Aluminum Oxide: A common polishing compound for stone and metal surfaces that produces a fine, smooth finish.

These polishing compounds are typically much less abrasive than buffing compounds, as their role is to refine the finish without significantly removing material from the surface.

Buffing provides a smooth or semi-gloss finish, depending on the compounds and techniques used. It’s highly effective at removing defects but does not provide the mirror-like shine associated with polishing. The results of buffing are typically seen in the surface’s evenness and reduction of imperfections. Depending on the desired outcome, buffing may leave a glossy finish or a satin sheen.

Polishing results in a high-gloss, reflective finish, which is ideal for surfaces where a mirror-like shine is desired. After polishing, the surface will appear highly reflective, and its shine will often be noticeable even from a distance. Polishing brings out the natural brilliance of the material, making it look glossy and pristine. This is particularly important in luxury goods like jewelry, fine wood furniture, and automotive finishes.

Feature | Buffing | Polishing |

Purpose | Remove imperfections and smooth rough surfaces | Create a high-gloss, reflective finish |

Process | Two-step (cut buffing + color buffing) | Single-step process using finer abrasives |

Materials Used | Coarser compounds (e.g., black emery, brown tripoli) | Finer abrasives (e.g., white or blue rouge) |

End Results | Smooth or semi-gloss finish | High-gloss, reflective finish |

Common Uses | Restoring surfaces, removing defects | Enhancing surface shine |

● Automotive Detailing: Buffing is commonly used to remove scratches, oxidation, and swirl marks from car paint. It smooths out imperfections and restores the shine before applying a protective layer.

● Furniture Restoration: Buffing restores the finish of wooden furniture, removing minor scratches and scuffs accumulated over time, ensuring the piece looks fresh and polished.

● Metal Surface Treatment: Buffing is used to smooth metal surfaces such as aluminum, copper, and brass. It helps remove blemishes and prepare the material for further treatments like polishing, coating, or painting.

● Jewelry Making: Polishing is widely used in the jewelry industry to create a mirror-like shine on metals, making pieces such as rings, necklaces, and bracelets look refined and appealing.

● Marble and Stone Finishing: Polishing enhances the natural beauty of stone surfaces, such as countertops and flooring, by giving them a shiny, reflective finish that highlights their texture.

● Wood Furniture Finishing: After buffing, polishing is used on wood furniture to achieve a high-gloss finish, enhancing its visual appeal and adding protection to the surface.

● Surface Imperfections: Buffing is the ideal technique when you need to smooth rough surfaces or remove visible imperfections like scratches, swirl marks, and oxidation. It’s the best method for preparing surfaces for further treatments or coatings.

● Restoration: If you’re restoring an old piece of furniture, car paint, or metal surface, buffing can help remove built-up grime and minor flaws, making the surface smoother and ready for polishing or other finishes.

● High-Gloss Finish: If you’re aiming for a high-gloss, reflective finish, polishing is the way to go. It works best on surfaces that are already relatively smooth but need an extra shine.

● Final Touch: Polishing is perfect for giving a surface that final touch of shine after buffing, creating a smooth, glossy look that makes the material stand out.

Despite the clear differences between buffing and polishing, many people still confuse the two. Let’s address some common misconceptions and provide helpful tips for using these techniques effectively:

● Reality: Buffing and polishing serve different purposes. Buffing is used to remove imperfections and smooth rough surfaces, while polishing is all about refining the surface to a high-gloss finish. While they can be used together, they yield different results and should not be treated as interchangeable.

● Reality: Both buffing and polishing involve removing material from the surface. However, polishing generally removes less material due to the finer abrasives used. Buffing is more aggressive and can remove more material, so it’s essential to control the pressure applied.

● Using the wrong buffing or polishing compounds can lead to poor results or even damage the surface. Always match the compound to the material and the specific stage of the process. For example, use a coarser compound for cut buffing and a finer compound for color buffing.

● For surfaces that need both restoration and a glossy finish, it’s a good idea to start with buffing to remove imperfections and then finish with polishing to create a mirror-like shine. This two-step process ensures the best results for surfaces that need both treatment and refinement.

Buffing and polishing serve different purposes. Buffing is ideal for removing imperfections and preparing surfaces, while polishing enhances the shine. Choosing the right technique depends on the surface condition, desired finish, and material type.

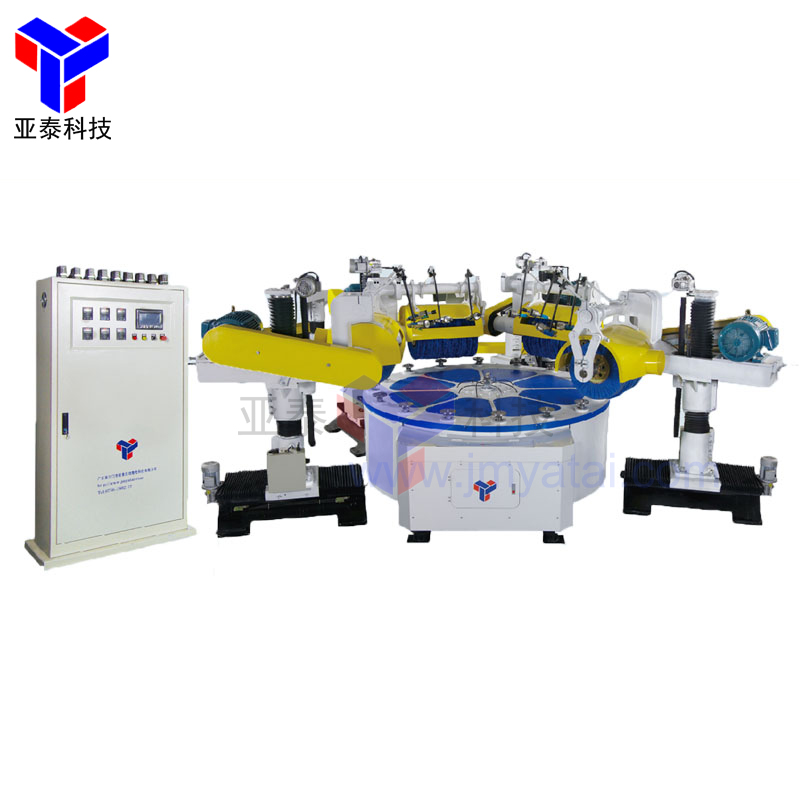

For those seeking high-quality results, products from Yatai Polishing Machine Co., Ltd. provide advanced solutions. Their polishing machines deliver precision and efficiency, ensuring optimal finishes for various materials.

A: Buffing is a more aggressive technique used to remove imperfections like scratches and oxidation, while polishing is a finer process that enhances the shine and smoothness of a surface.

A: Use buffing when you need to remove visible defects or rough areas. Polishing is ideal when you want to achieve a high-gloss finish on a relatively smooth surface.

A: If done incorrectly, buffing can remove too much material, potentially damaging the surface. Always use the right compound and technique for the material.

A: Polishing creates a higher gloss and more reflective finish than buffing, which focuses on surface imperfections rather than shine.

A: The cost of buffing and polishing depends on the equipment, materials, and surface area. Generally, polishing may cost more due to the finer materials used.

A: You need a buffing machine and specific compounds for buffing. For polishing, finer abrasives and polishing machines or pads are required for a reflective finish.