Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-16 Origin: Site

Are you confused about the differences between grinding, sanding, polishing, and deburring? These processes play a critical role in achieving high-quality finishes in manufacturing. Each method serves a unique purpose, but how do they differ?

In this article, we will explore the core distinctions between these processes and explain what specific challenges each one addresses. By the end, you'll understand when to use each technique for optimal results.

Grinding is a precision machining process used to remove material from the surface of a workpiece by utilizing an abrasive tool or grinding wheel. The process involves the use of a rotating abrasive surface that cuts away small amounts of material from the workpiece. Grinding is commonly used in industries that require high precision, especially when working with hard materials like metals, ceramics, and hard plastics.

The primary goal of grinding is to refine a workpiece's dimensions and surface smoothness. Grinding is typically performed after other processes, such as casting or forging, to correct any irregularities or dimensional errors. It also helps achieve tight tolerances and fine surface finishes. When exact geometries and smooth surfaces are required, grinding is an essential technique in the production process.

Grinding is widely used in industries that require precise dimensions and smooth surfaces. It is commonly employed in metalworking, automotive, aerospace, and toolmaking. Grinding is also essential in manufacturing parts for machines, engines, and electronic devices, where accuracy is critical.

● Precision Machinery: Grinding is used to shape metal parts for machines, where tight tolerances are crucial.

● Tool Sharpening: It is commonly used to sharpen cutting tools like drills and end mills, ensuring they maintain their effectiveness during use.

● Surface Preparation: Grinding is often the first step in preparing materials for further treatments like coating or polishing.

● Metal Parts for Precision Machinery: Grinding is used to shape and smooth metal components like gears, shafts, and bearings, ensuring that they fit precisely and operate smoothly.

● Smoothing Plastic Components: Grinding can be used to smooth the surfaces of plastic components, preparing them for further treatments or final assembly.

● Tool Sharpening: Tools such as chisels, blades, and drills are regularly sharpened using grinding machines to restore their cutting edges.

Sanding is a process that involves the use of abrasive materials, typically sandpaper or sanding belts, to smooth out surfaces by removing imperfections and roughness. This technique uses abrasives with various grit sizes, from coarse to fine, to gradually achieve a smoother surface.

The primary purpose of sanding is to prepare a surface for further finishing, such as painting, coating, or staining. It is also used to remove large flaws or rough patches on a workpiece, providing an even and consistent surface. Unlike grinding, which is often used to shape or resize a part, sanding is mainly focused on achieving a smooth and aesthetically pleasing surface.

Sanding is widely used in woodworking, metalworking, and automotive industries. It is commonly applied as a preparatory step before other finishing techniques, ensuring that the surface is smooth and ready for painting or coating.

● Woodworking: Sanding is essential in the woodworking industry, where it is used to smooth wooden surfaces before applying finishes like paint, varnish, or stain.

● Automotive Bodywork: Sanding plays a key role in automotive repair and customization, where it is used to remove imperfections and smooth out dents and scratches in metal car bodies.

● Metalworking: Sanding is also used in metalworking to smooth the surface of metal parts, removing marks left from cutting or welding processes.

● Furniture Making: Sanding is crucial in preparing wood surfaces for finishes. It helps remove rough patches and ensures the wood is ready for staining, painting, or varnishing.

● Automotive Bodywork: In automotive repair, sanding is used to remove dents, rust, or old paint, leaving a smooth surface ready for painting or coating.

● Plastic Parts: Sanding is commonly used in the production of plastic components, where a smooth surface is required for both aesthetic and functional purposes.

Polishing is the process of refining the surface of a material to remove microscopic imperfections, scratches, pits, and oxidation. The purpose is to create a smooth, glossy, and visually appealing finish. Polishing usually involves the use of fine abrasives or polishing compounds applied with a soft cloth or polishing wheel.

The main objective of polishing is to enhance the aesthetic qualities of a workpiece. It is used to achieve a smooth, high-gloss finish that improves both the appearance and the durability of the material. In addition to enhancing surface aesthetics, polishing also removes fine scratches and oxidation, contributing to the material's overall longevity.

Polishing is essential in industries that require high-quality, glossy finishes. It is widely used in automotive, jewelry, medical devices, electronics, and precision instruments where surface appearance and smoothness are critical.

● Automotive Industry: Polishing is used to achieve the shiny, reflective surfaces on car parts, including bumpers, wheels, and engine components.

● Jewelry: Polishing is essential in the jewelry industry to achieve a mirror-like finish on precious metals like gold, silver, and platinum.

● Medical and Electronic Devices: Polishing is often required for devices that need to maintain smooth surfaces, such as medical instruments and electronic components.

● Automotive Parts: Polishing is used to give automotive components like bumpers and exhaust pipes a high-gloss, shiny finish that enhances their visual appeal.

● Jewelry Making: In jewelry making, polishing is essential to achieve the smooth, reflective surfaces that make pieces like rings and necklaces visually striking.

● Medical Instruments: Polishing is used in medical instruments to ensure that surfaces are smooth, reducing the potential for bacteria buildup and improving hygiene.

Deburring is the process of removing burrs, sharp edges, or protrusions that form on a workpiece during machining, cutting, or forming. These burrs can cause safety hazards, interfere with assembly, and reduce the functionality of the part.

The goal of deburring is to eliminate sharp edges and protrusions that can pose risks during handling, assembly, or use. Burrs are common in manufacturing processes like drilling, milling, and laser cutting, and they must be removed to ensure that the parts are safe to handle and properly fit together.

Deburring is essential in industries such as metalworking, plastics manufacturing, and machining, where parts with sharp edges could cause injury or affect the proper assembly of products. It is widely used in precision engineering to ensure that all parts fit correctly in assemblies and work smoothly during operation.

● Metalworking: In metalworking, deburring is commonly done after laser cutting, machining, or stamping processes to ensure that sharp edges are removed from the metal parts.

● Plastic Molding: Plastic parts created through molding processes often have burrs that must be removed to ensure proper assembly and functionality.

● Machining: In the machining industry, deburring is used to clean up edges and ensure that parts fit together seamlessly.

● Laser Cut Metal Sheets: After laser cutting metal, deburring removes sharp edges and fragments that could cause injury during handling or lead to improper fitting in later assembly stages.

● Plastic Molding: Deburring is essential after the injection molding process, where the removal of flash (excess material) ensures smooth edges and proper fit during assembly.

● Precision Components: After precision machining, deburring removes any sharp edges from small mechanical components like gears or screws, ensuring that they fit properly in larger assemblies.

While grinding, sanding, polishing, and deburring are the primary surface finishing techniques, there are other methods that provide unique effects and finishes for specific applications. These processes include brushing, lapping, buffing, honing, and satin finishing.

Brushing is a method used to clean or texture metal surfaces using a rotating brush. It is effective at removing contaminants like rust or oxide layers and can also provide a textured finish on metals, improving both appearance and functionality.

Lapping is a highly precise process used to achieve a fine surface finish. It involves using a specially formulated abrasive medium to refine surfaces to achieve a smooth, highly controlled surface finish. This technique is common in the manufacture of high-precision components like those used in optics and semiconductor industries.

Buffing is a surface finishing process that creates a high-gloss finish. It is similar to polishing, but it uses softer materials like a buffing wheel combined with polishing compounds. Buffing is ideal for producing a shiny finish on both metals and plastics.

Honing is used to improve the interior surface of holes. It is a precision process used to achieve exact dimensions and smoothness, making it particularly useful in automotive applications like refining engine cylinders or hydraulic components.

Method | Purpose | Applications |

Brushing | Removes contaminants and adds texture to surfaces. | Metal cleaning, aerospace, automotive. |

Lapping | Achieves precise, smooth finishes. | Optics, semiconductors. |

Buffing | Creates high-gloss finishes on metals and plastics. | Automotive, jewelry, appliances. |

Honing | Improves interior surfaces for precision. | Automotive engine cylinders, hydraulics. |

Definition: Satin finishing creates a non-glossy, matte surface by using abrasive tools to evenly rub the material. This technique helps eliminate shine while maintaining a smooth texture.

Applications: Satin finishes are often used in decorative or functional parts where reflection needs to be minimized, such as in architectural metal finishes, electronics, or consumer goods.

Definition: Chamfering is the process of removing sharp edges from the corners of a workpiece to create a beveled or angled surface. It helps improve the part's functionality and aesthetics.

Applications: Chamfering is used in metalworking and machining, particularly for parts that need to fit together during assembly. It is also used to prevent sharp edges that could cause damage or injury.

Definition: Edge rounding is a finishing process that rounds sharp edges to improve the part’s safety and reduce stress concentration that might cause fractures or failures.

Applications: Edge rounding is essential for many mechanical components that will be handled frequently. It ensures that parts are safe to use and increases the durability of the finished product.

Different materials require different surface treatment methods. Metals, plastics, and ceramics all behave differently under abrasive processes, so choosing the appropriate technique is essential for achieving the desired results.

If your goal is to enhance the gloss or shine of a part, polishing is the way to go. If safety is a concern, deburring should be prioritized. For achieving precision shapes and smooth surfaces, grinding is the best option.

Efficiency and cost-effectiveness are crucial when choosing the right surface treatment method. Consider the production scale and material characteristics to select the process and equipment that offers the best balance between speed, quality, and cost.

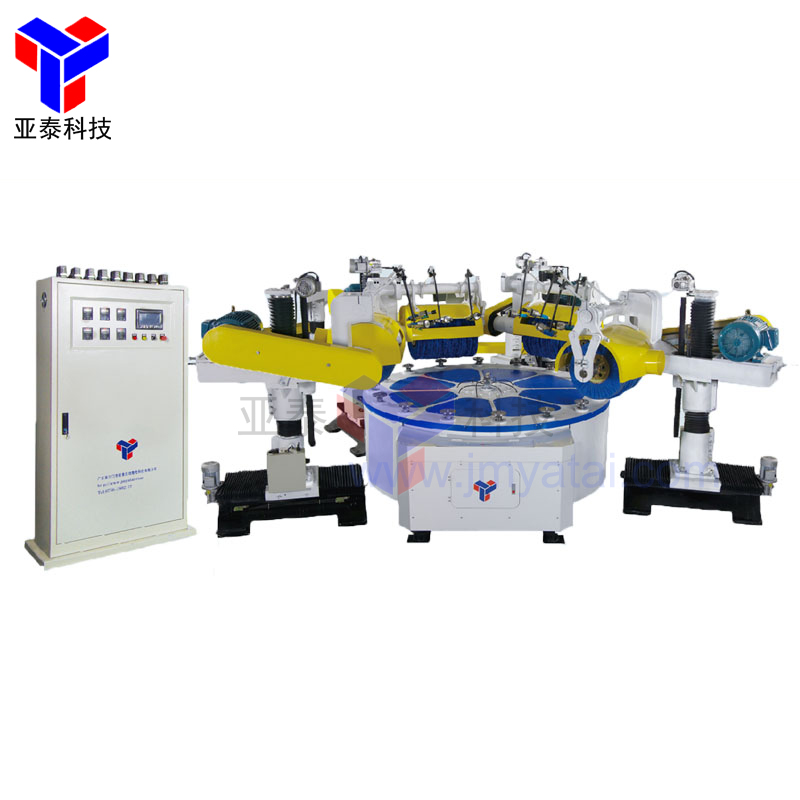

Grinding, sanding, polishing, and deburring each serve unique purposes in manufacturing. Choosing the right method ensures optimal product quality and efficiency. Selecting the correct process is crucial to achieving precise finishes, improving functionality, and enhancing safety. Companies like Yatai Polishing Machine Co., Ltd. offer specialized equipment that makes these processes more efficient, helping manufacturers achieve high-quality results while saving time and costs.

A: Grinding removes material using an abrasive tool for precision, while sanding smooths surfaces, often to remove large imperfections. Grinding is more for shaping, sanding for surface preparation.

A: Polishing enhances surface gloss and aesthetics, removing fine scratches. It is essential for achieving high-quality finishes in products like automotive parts and jewelry.

A: Deburring removes sharp edges or burrs from workpieces, preventing injury during handling and ensuring parts fit properly in assembly.

A: Use sanding to smooth rough surfaces and remove imperfections. Polishing is for refining the surface to a glossy, smooth finish after sanding or grinding.